In cutting-edge rapid-paced commercial enterprise panorama, locating materials that integrate sturdiness, capability, and price-effectiveness has emerged as more and more essential. Among the maximum bendy solutions available, metallized doggy film sticks out as an activity-changing fabric that has revolutionized multiple industries. From food packaging to electronics protection, this remarkable material gives homes that make it essential for countless applications.

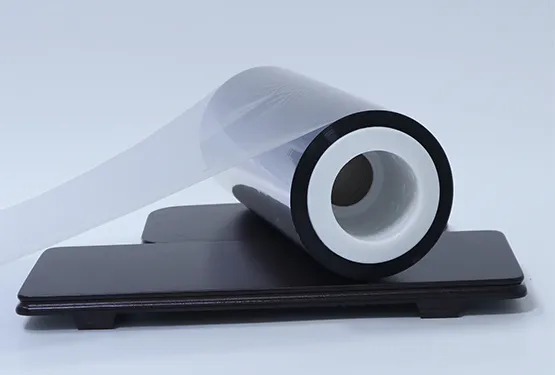

Understanding what makes metallized PET film so treasured requires looking past its floor. This specialised fabric combines the strength and flexibility of polyethylene terephthalate (PET) with the reflective and barrier houses of a skinny steel coating, normally aluminum. The cease result is a fabric that guarantees notable ordinary performance across numerous business dreams.

What Makes Metallized PET Film Special?

The production machine at the back of metallized PET movie involves depositing an ultra-skinny layer of metal onto a PET substrate via vacuum metallization. This manner creates a cloth that keeps the flexibility and transparency of the bottom movie whilst adding metallic homes that dramatically decorate its functionality.

The thickness of the metal layer is precisely controlled, normally measuring just a few nanometers. Despite this minimum thickness, the metal coating provides big upgrades in barrier houses, moderate mirrored image, and electromagnetic protecting skills. This precision engineering makes metallized PET film an outstanding desire for applications requiring particular performance characteristics.

Due to its enhanced barrier protection and durability, metallized PET film is widely used in packaging industries where product integrity is critical. For example, companies that buy drug test kit packaging materials often rely on metallized PET film to protect sensitive diagnostic components from moisture, oxygen, and light exposure. This ensures that the kits maintain their accuracy and reliability throughout storage and transportation.

Key Applications Across Industries

Food and Beverage Packaging

The food corporation has embraced metallized PET movie for its splendid barrier houses in opposition to moisture, oxygen, and light. These traits assist enlarge shelf existence even as retaining product freshness and terrific. Snack food packages, coffee baggage, and ready-to-eat meal boxes frequently utilize this material to protect contents from environmental elements that could compromise taste and dietary cost.

The film’s potential to face up to temperature versions makes it suitable for products requiring hot-fill processing or the ones stored in numerous temperature situations. Additionally, its printability permits producers to create appealing packaging designs at the identical time as retaining product safety.

Electronics and Electromagnetic Shielding

Modern digital devices face growing stressful conditions from electromagnetic interference (EMI). Metallized pet movie presents a powerful solution by using a way of developing a conductive barrier that shields touchy additives from undesirable electromagnetic radiation. This application is mainly vital in smartphones, pills, car electronics, and medical gadgets where interference could compromise functionality or protection.

The film’s flexibility allows it to conform to complex shapes and tight spaces within digital assemblies, making it extra practical than inflexible shielding substances. Its light-weight nature additionally contributes to regular tool weight loss, a critical problem in portable electronics.

Thermal Management and Insulation

The reflective houses of metallized PET film make it incredible for thermal control programs. In constructing introduction, it serves as radiant barrier fabric, reflecting warmness faraway from structures to decorate power efficiency. The vehicle company uses it in heat shields and thermal limitations to protect touchy additives from engine warmth.

Space applications additionally benefit from these thermal houses, with metallized puppy film serving as lightweight thermal manipulate substances in satellites and spacecraft. Its functionality to reflect sun radiation at the same time as keeping structural integrity in extreme situations makes it valuable for aerospace applications.

Advantages That Set It Apart

The precise aggregate of houses offered via metallized PET movie creates advantages that conventional materials cannot. Its incredible tensile strength guarantees durability in the course of handling and processing, at the same time as the metal coating offers more suitable barrier residences without considerably increasing weight or thickness.

Chemical resistance is every other splendid gain, allowing the cloth to preserve universal overall performance at the same time as exposed to numerous chemicals and environmental conditions. This stability makes it suitable for long-term applications wherein cloth degradation has to compromise overall performance.

The cloth’s printability permits custom branding and identification, vital elements in customer-managing packages. Unlike a few barrier substances that require unique printing techniques, metallized puppy movies may reveal the usage of traditional techniques, simplifying manufacturing workflows.

Environmental Considerations and Sustainability

Modern industries increasingly prioritize sustainable substances and approaches. Metallized PET film contributes to environmental dreams via several mechanisms. Its barrier houses assist in reducing meal waste via extending shelf life, at the same time as its light-weight nature reduces transportation electricity necessities.

The material’s recyclability, while properly processed, aligns with spherical economic machine ideas. Many producers now offer specialised recycling programs for metallized movies, assisting corporations meet sustainability goals whilst retaining usual performance requirements.

Choosing the Right Metallized PET Film

Selecting the proper metallized pet film calls for data particular software requirements. Factors alongside barrier level, optical houses, temperature resistance, and processing compatibility must be evaluated. Working with skilled carriers ensures pinnacle-great fabric preference and application success.

Thickness options commonly range from 6 microns to 350 microns, with every thickness providing special general performance trends. Thinner movies offer flexibility and conformability, while thicker alternatives offer improved barrier houses and durability.

Future Outlook and Innovation

The metallized PET movie enterprise keeps evolving with advancing era and changing marketplace needs. New coating substances and alertness strategies are expanding feasible programs, at the same time as progressing manufacturing techniques are improving average performance and lowering prices.

Emerging applications in renewable strength, flexible electronics, and smart packaging exhibit the material’s adaptability to destiny technological desires. As industries are searching for substances that integrate multiple abilities in single solutions, metallized doggy film is placed to play an increasingly crucial function.

Conclusion

Metallized PET film represents an incredible example of ways fabric generation innovation can cope with diverse business stressful conditions. Its precise mixture of homes makes it an invaluable material for packages starting from normal patron products to superior technological structures.

Whether you’re developing new products, enhancing gift programs, or on the lookout for price-effective answers to complicated cloth challenges, exploring the possibilities provided via metallized puppy film may want to lose large benefits on your tasks.

Ready to find out how metallized PET movies can decorate your packages? Visit shieldingtape.Com to discover our comprehensive choice of excellent metallized films and locate the right answer on your unique goals. Our institution of experts is prepared to help you perceive the proper material specifications for your subsequent mission.